Pharmaceutical Intermediates

Pharmaceutical intermediates are essential for synthesizing active pharmaceutical ingredients (APIs), tailored for specific therapeutic areas such as antibiotics, anticancer drugs, and cardiovascular treatments. These intermediates are characterized by high purity, chemical stability, and scalability, ensuring compliance with stringent international standards.

We provide customized solutions and extensive technical support, meeting the rigorous demands of pharmaceutical development and facilitating efficient commercialization.

Our Key Categories of Pharmaceutical Intermediates

Key Features of Our Pharmaceutical Intermediates

High Purity and Quality

Our pharmaceutical intermediates are rigorously produced under stringent quality control measures, ensuring unmatched purity and consistent excellence, pivotal for efficacious drug synthesis.

Chemical Stability

We guarantee optimal chemical stability of our intermediates under prescribed storage conditions, preserving their effectiveness for seamless integration into final pharmaceutical products.

Precision and Consistency

Each batch of our intermediates is characterized by precise molecular structure and batch-to-batch consistency, crucial for reliable performance in the synthesis of active pharmaceutical ingredients (APIs).

Scalability

Our production processes are meticulously designed to support scalability, facilitating seamless scale-up to meet global demands without compromising quality.

Regulatory Compliance

All intermediates are manufactured in compliance with stringent regulatory standards, including those set by the FDA and EMA, ensuring adherence to safety, environmental, and ethical guidelines.

Practical and Economical Synthesis Routes

We employ economically viable and practical synthesis routes, utilizing cost-effective raw materials and state-of-the-art technologies to maximize efficiency.

Compatibility

Our intermediates are engineered to be compatible with a variety of solvents and reaction conditions, ensuring they do not interfere with catalysts or subsequent synthesis steps.

Flexible Production Capabilities

Our flexible manufacturing capabilities allow us to accommodate both small-scale custom projects and large-scale production requirements, ensuring versatility and responsiveness to client needs.

Customization

We specialize in customizing our intermediates to meet specific client requirements, adapting our products to suit unique therapeutic and market needs.

Key Applications of Our Pharmaceutical Intermediates

We demonstrate the critical role our pharmaceutical intermediates play in various facets of pharmaceutical and chemical manufacturing, showcasing our commitment to excellence, quality, and innovation.

Synthesis of Active Pharmaceutical Ingredients (APIs)

Our intermediates are integral to the synthesis of APIs, providing high-purity and reliable starting materials essential for the production of safe and effective pharmaceuticals.

Analytical and Quality Control Testing

Our high-purity intermediates are used in analytical and quality control laboratories to ensure the accuracy and precision of test results, supporting stringent quality assurance processes.

Pharmaceutical Research and Development

We supply intermediates that are critical for pharmaceutical R&D, facilitating innovative drug discovery and development efforts with customizable and high-quality materials.

Biotechnology

Our products support various biotechnological applications, contributing to the development and manufacturing of cutting-edge biotechnological solutions in the medical and pharmaceutical fields.

Specialty Chemicals

We provide high-quality intermediates for the production of specialty chemicals, ensuring stability and performance in specific, high-value applications.

Regulatory Compliance and Certification

Our intermediates are used in regulatory compliance testing, aiding pharmaceutical companies in meeting international safety, efficacy, and quality standards required by bodies such as the FDA and EMA.

Why Choose Our Pharmaceutical Intermediates

By choosing us, you benefit from a comprehensive range of advantages that not only enhance the quality and efficiency of your pharmaceutical processes but also provide you with a reliable and innovative partner dedicated to your success.

Unmatched Quality and Purity

Our pharmaceutical intermediates are produced with the highest standards of quality control, ensuring exceptional purity and consistent quality essential for reliable pharmaceutical synthesis.

Advanced R&D Capabilities

We have a dedicated team of experienced researchers and scientists who continuously develop innovative solutions to meet the evolving needs of the pharmaceutical industry, ensuring you stay ahead in a competitive market.

Comprehensive Regulatory Compliance

We strictly adhere to global regulatory standards, including FDA, EMA, and other international bodies, ensuring our products meet the highest safety, environmental, and ethical standards.

Scalable and Flexible Production

Our state-of-the-art manufacturing facilities are designed for scalability, allowing us to increase production volumes without compromising quality. We offer flexible production capabilities to accommodate both small-scale trials and large-scale commercial manufacturing.

Reliable Supply Chain Management

We maintain a robust supply chain management system to ensure timely delivery and minimize the risk of disruptions. Our efficient logistics and global distribution network guarantee that you receive your products when and where you need them.

Customization and Tailored Solutions

We understand that each project has unique requirements. Our team works closely with clients to provide customized intermediates and tailored solutions that meet specific needs, ensuring optimal performance and compatibility in your applications.

Cost-Effective Solutions

We provide high-quality pharmaceutical intermediates at competitive prices, ensuring you receive excellent value without compromising on quality or performance.

Expertise in Specialty Chemicals

Our deep expertise in the synthesis and purification of specialty chemicals means you can rely on us for complex and high-precision intermediates required for advanced pharmaceutical applications.

Customer-Centric Focus

Our customer-centric approach means we prioritize your needs and satisfaction, striving to exceed your expectations with every interaction and product we deliver.

How do we work

Our Customer-Centric Approach

At Reisch, our mission is to provide exceptional cosmetic ingredients and unparalleled support to help you create outstanding beauty products.

We begin with a thorough consultation to understand your specific requirements and project objectives. Our team gathers detailed information to fully comprehend your operational needs and challenges.

Our R&D team customizes solutions to meet your unique specifications. Leveraging advanced technologies and industry expertise, we design and produce pharmaceutical intermediates precisely aligned with your requirements.

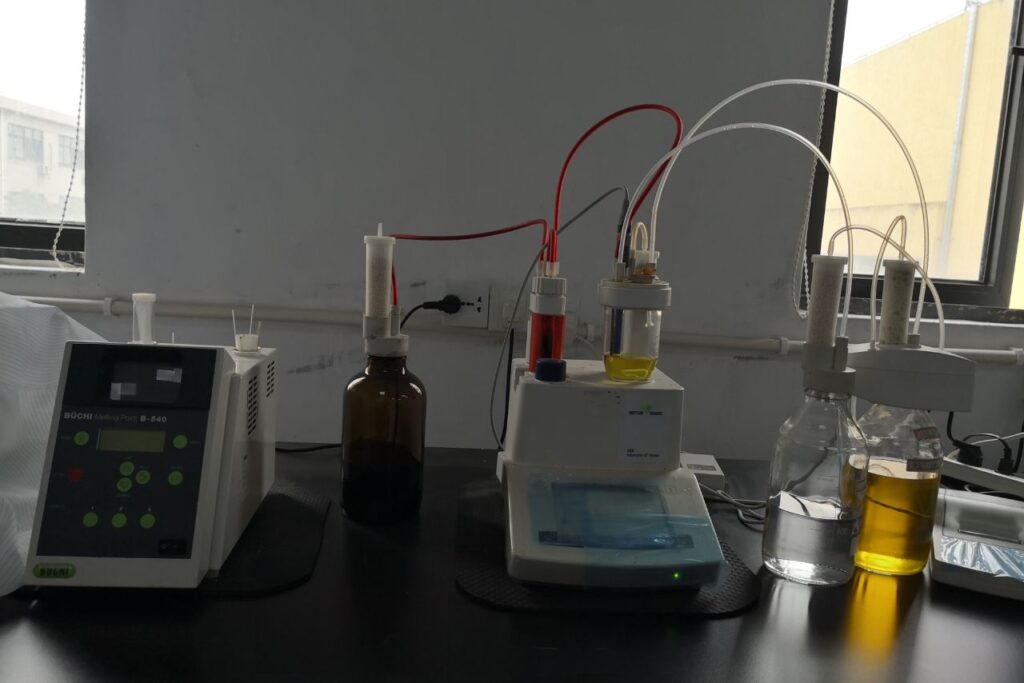

Quality is prioritized at every production stage. From raw material selection to final product testing, our intermediates undergo rigorous quality control to ensure they meet the highest standards of purity, consistency, and regulatory compliance.

Our state-of-the-art manufacturing facilities offer flexibility and scalability. Whether for small-scale pilot production or large-scale commercial manufacturing, we ensure efficient operations and timely delivery without compromising quality.

We provide comprehensive documentation, including Certificates of Analysis (CoA), Material Safety Data Sheets (MSDS), and complete manufacturing records. This ensures full traceability and adherence to international regulatory standards.

Our robust supply chain management guarantees efficient and timely delivery. We collaborate with trusted logistics partners to manage transportation and distribution, minimizing delays and ensuring project timelines are met.

We offer ongoing technical support to ensure seamless application and integration of our intermediates. Our specialists provide expert guidance, troubleshoot issues, and address queries to ensure successful implementation and optimal performance.

We value customer feedback as part of our commitment to continuous improvement. Regularly incorporating client insights, we enhance our products and services to meet evolving needs and exceed expectations.

We are dedicated to delivering superior pharmaceutical intermediates and unparalleled customer support at every stage. Partnering with us means gaining a reliable partner committed to excellence, innovation, and your success in the pharmaceutical industry.

Top Company

99%

Testimonial

Client Feedback & Reviews

The Ultimate Guide to Acquiring High-Quality Pharmaceutical Intermediates

In the global pharmaceutical and healthcare sectors, securing high-quality pharmaceutical intermediates is crucial. This comprehensive guide outlines the critical steps to ensure you source the best products for your manufacturing needs.

Table of Contents

Understanding Pharmaceutical Intermediates

Pharmaceutical intermediates are essential compounds used in the synthesis of active pharmaceutical ingredients (APIs). They must demonstrate consistent purity and stability to guarantee the efficacy of final drug products. Adhering to strict regulatory standards and ensuring precise molecular structures are paramount.

Key Steps to Acquiring High-Quality Intermediates

Define Your Requirements

Identify the specific intermediates necessary for your production processes. Precise knowledge of chemical properties and quality standards is essential for selecting the appropriate supplier.

Conduct Comprehensive Supplier Research

Identify the specific intermediates necessary for your production processes. Precise knowledge of chemical properties and quality standards is essential for selecting the appropriate supplier.

Verify Supplier Credentials

Ensure potential suppliers comply with international regulatory standards, such as those set by the FDA and EMA. Verify their certifications and quality assurance processes to ensure compliance and reliability.

Request Detailed Samples and Documentation

Prior to committing to a bulk purchase, request samples to evaluate the intermediates within your processes. Additionally, obtain comprehensive documentation covering the manufacturing process, origin, and distribution pathways.

Assess Quality Control Procedures

Thoroughly review the supplier’s quality control measures. Reliable suppliers will have stringent testing and verification protocols in place to ensure the purity and stability of their intermediates.

Negotiate Clear Terms and Conditions

Discuss and agree upon terms related to pricing, logistics, and payment methods. Ensure that delivery schedules align with your production timelines to prevent delays and missed peak sales periods.

Finalize and Secure the Purchase

Once satisfied with the quality and terms, proceed with the purchase. Establish clear communication channels with the supplier to facilitate smooth transactions and address any issues promptly.

Conclusion

Securing high-quality pharmaceutical intermediates requires meticulous planning and thorough evaluation. By following these steps, you can ensure that you source reliable and effective intermediates, thereby upholding the integrity and success of your pharmaceutical products.

For more detailed information or to discuss your specific requirements, please contact us at [email protected].

Common Questions

Most Popular Questions

Our commitment to quality is unwavering. We employ rigorous quality control protocols at every stage of production, from raw material procurement to final product testing. Each batch undergoes extensive testing to ensure it meets the highest standards of purity, consistency, and performance.

Absolutely. We offer bespoke synthesis services to fulfill unique client requirements. Our R&D team collaborates closely with clients to develop tailored solutions that align perfectly with your project goals and specifications.

We supply comprehensive documentation for all our products, including Certificates of Analysis (CoA), Material Safety Data Sheets (MSDS), and detailed records of the manufacturing process. This thorough documentation ensures full traceability and regulatory compliance.

Our intermediates are manufactured in strict accordance with international regulatory standards, including those set by the FDA and EMA. We ensure all products meet the necessary safety, environmental, and ethical guidelines mandated by these authorities.

Our advanced manufacturing facilities are designed for scalability, accommodating both small-scale pilot production and large-scale commercial manufacturing. This ensures efficient operations and timely delivery to meet your project timelines.

We maintain a robust supply chain management system to guarantee efficient and timely product delivery. Partnering with trusted logistics providers, we ensure the seamless transportation and distribution of your orders, minimizing potential delays.

Yes, we offer samples of our pharmaceutical intermediates for testing and evaluation. Please reach out to our sales team to discuss your sample requirements, and we will arrange for the appropriate samples to be sent to you.

Our standard payment terms are typically specified in the sales agreement. We offer flexible payment options to meet the diverse needs of our clients. Please discuss specific payment terms with our sales team during the order process.

We understand the importance of confidentiality and intellectual property protection. We adhere to strict confidentiality agreements and take all necessary measures to safeguard your proprietary information throughout our collaboration.

Our dedication to quality, innovation, and customer satisfaction sets us apart. With advanced R&D capabilities, stringent quality control, and comprehensive customer support, we provide unmatched value and reliability to our clients.

Our typical delivery time varies depending on the product and order quantity. However, we strive to ensure prompt and efficient delivery for all orders. For standard orders, delivery times usually range from 2 to 4 weeks after order confirmation. For custom synthesis or large-scale orders, delivery times will be discussed and agreed upon based on the specific requirements of the project. We prioritize clear communication and reliability to ensure that your products arrive on time and in perfect condition.

Customer satisfaction is our priority. We have a dedicated team to handle feedback and complaints promptly. If you have any concerns, please contact us, and we will work with you to resolve the issue swiftly.

To place an order or request a quote, please contact our sales team via email at [email protected] or visit our website at www.reischbio.com. Our team will promptly respond to your inquiry and provide the necessary assistance.