Understanding advanced composites feels overwhelming. Their specialized nature can seem out of reach. This article breaks it down, making complex ideas easy to grasp.

We can explore advanced composite applications by examining their diverse uses, from aerospace to sports. We also need to understand custom chemical manufacturing's vital role. It creates the unique resins and additives these high-performance materials require for success.

"Exploring Advanced Composites and Custom Chemicals"

"Exploring Advanced Composites and Custom Chemicals"

Are you ready to really understand advanced composites? It's a fascinating world, and I want to show you just how these materials are changing industries. We'll look at what they are, how they're made, and why custom chemical manufacturing is so important. This journey will show you the critical link between making great products and the special chemicals that go into them. Let's start exploring.

What are the applications of advanced composite materials?

You hear "advanced composites" a lot. But where do we actually see them? Not knowing their real-world uses means you might miss out on using them in your own projects. Let's look at where these materials shine.

Advanced composite materials are key in aerospace, automotive, marine, sports equipment, and construction. They offer amazing strength for their weight and last a long time. This makes them perfect for tough jobs where performance truly matters.

Various applications of advanced composite materials

Let's dive deeper into where these materials make a difference.

The range of applications is quite broad, and it's growing all the time. The unique properties of advanced composites, primarily their high strength-to-weight ratio and corrosion resistance, make them suitable for many demanding situations.

Key Application Areas:

- Aerospace: This was one of the first big areas for composites. Think about aircraft wings, fuselage sections, and even interior components. Satellites and spacecraft also rely heavily on them because every gram saved in weight means lower launch costs and better performance. I remember a client who was developing a new type of unmanned aerial vehicle (UAV). The weight targets were incredibly strict. We explored several options, but advanced carbon fiber composites were the only way to meet the strength and weight requirements. Sourcing the right pre-impregnated fibers (prepregs) with a specific resin system was a challenge, which really highlighted the role of specialized chemical suppliers.

- Automotive: High-performance race cars, like those in Formula 1, use composites extensively for chassis and body panels to be light and strong. We're also seeing them more in everyday cars to improve fuel efficiency and safety. Electric vehicles, in particular, benefit from lightweight components to extend battery range.

- Marine: Boat hulls, masts, and decks are often made from composites. They resist saltwater corrosion and can be molded into efficient hydrodynamic shapes. I once helped a small boat builder switch from traditional fiberglass to a more advanced composite lay-up. The new boats were lighter, faster, and much more durable, which really boosted their reputation.

- Sports Equipment: This is an area many of us can relate to. Tennis rackets, bicycle frames, golf club shafts, skis, and snowboards often use composites for better performance. They allow for designs that are stiff where needed and flexible elsewhere, all while keeping weight down.

- Construction and Infrastructure: We're seeing composites used to reinforce bridges, create lightweight architectural elements, and even in pipes and tanks due to their corrosion resistance.

The common thread here is the need for materials that outperform traditional ones like steel or aluminum in specific ways, especially when weight, strength, or durability are critical.

What are the methods of preparation of composite materials?

Knowing composites are useful is one thing. But how are they actually put together? Without understanding the preparation methods, you can't really optimize a design or choose the best way to manufacture a part. Let's look at the common ways these materials are made.

Composite materials are typically prepared using methods like hand lay-up, spray lay-up, filament winding, pultrusion, and resin transfer molding (RTM). Each method suits different shapes, production numbers, and cost targets, offering tailored solutions.

Different methods of composite material preparation

Let's dive deeper into how these materials are actually formed. The choice of preparation method is crucial. It depends on the part's complexity, the number of parts needed, the required performance, and, of course, the budget.

Common Preparation Methods:

- Hand Lay-up: This is one of the oldest and simplest methods. Layers of reinforcing fabric (like carbon or glass fiber cloth) are placed by hand into a mold. Liquid resin is then applied with brushes or rollers to saturate the fabric. It’s labor-intensive but good for large, complex shapes and prototypes. In my early factory days, we did a lot of custom one-off parts using hand lay-up. It gave us great flexibility.

- Spray Lay-up: In this method, short chopped fibers and catalyzed resin are sprayed simultaneously onto a mold surface. It's faster than hand lay-up for certain applications but generally results in parts with lower strength due to the shorter, randomly oriented fibers.

- Filament Winding: This process is used to make cylindrical or pipe-like structures. Continuous strands of fiber (filaments) are drawn through a resin bath and then wound onto a rotating mandrel (a core mold). The winding pattern can be controlled to achieve specific strength characteristics. This is great for pressure vessels and pipes.

- Pultrusion: Think of this like extruding plastics, but for composites. Continuous fibers are pulled from creels, guided through a resin bath for impregnation, and then pulled through a heated die. The die shapes the profile and cures the resin. This method is excellent for making constant cross-section profiles like beams, channels, and rods. I worked with a company that made composite utility poles using pultrusion – incredibly strong and weather-resistant.

- Resin Transfer Molding (RTM) and Vacuum Assisted RTM (VARTM): In RTM, dry reinforcing fibers are placed into a closed mold. Resin is then injected under pressure. VARTM is similar but uses a vacuum to help draw the resin through the fibers. These methods are good for producing complex parts with good surface finish on both sides and offer higher production rates than hand lay-up. The precision needed for the resin flow and cure often relies on custom-formulated resins.

Choosing the right method requires understanding the trade-offs between tooling cost, labor cost, material waste, production speed, and the final mechanical properties of the part.

What can be used to make advanced composites?

The term "advanced composites" sounds very technical. So, what are the actual ingredients? If you don't know what goes into them, it's hard to pick the right composite for a specific job or understand why they behave the way they do. Let's break down these building blocks.

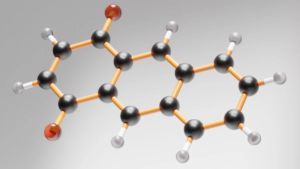

Advanced composites are primarily made from two main components: reinforcing fibers (like carbon, glass, or aramid) and a matrix material, which is usually a polymer resin (like epoxy, polyester, or vinyl ester). Special additives can also be included.

Reinforcing fibers and polymer resin matrix

Let's dive deeper into the components that make up these remarkable materials. The magic of composites comes from combining the strengths of different materials.

Core Components:

- Reinforcing Fibers: These are the backbone of the composite, providing the primary strength and stiffness. The type of fiber used has a huge impact on the final properties.

- Carbon Fibers: Known for their exceptional stiffness, high tensile strength, and low weight. They are often the go-to for high-performance applications in aerospace and top-tier sports equipment. They can be expensive, though.

- Glass Fibers (E-glass, S-glass): More common and less expensive than carbon fibers. E-glass is the standard, offering good strength and electrical insulation. S-glass is a higher-strength version. Widely used in boats, automotive parts, and industrial applications.

- Aramid Fibers (e.g., Kevlar®, Twaron®): These fibers are known for their high impact resistance, toughness, and good tensile strength-to-weight ratio. They are used in ballistic protection, and to add toughness to other composite structures.

- Matrix Materials (Binder): The matrix surrounds the fibers, holds them in place, transfers load between them, and protects them from environmental damage. The vast majority of advanced composites use polymer matrices.

- Thermosetting Resins: These resins cure (harden) through a chemical reaction, often initiated by heat or a catalyst, and cannot be remelted.

- Epoxy Resins: Very popular for advanced composites due to their excellent adhesion to fibers, high mechanical properties, good chemical resistance, and low shrinkage during cure. They are often used with carbon and aramid fibers. Custom chemical manufacturers play a huge role here, tailoring epoxy formulations for specific cure times, viscosities, and temperature resistances. I’ve relied on these custom solutions many times to meet tricky project requirements.

- Polyester Resins: Lower cost than epoxies, commonly used with glass fibers for general-purpose applications like boat hulls, car body panels, and tanks.

- Vinyl Ester Resins: Offer better toughness and chemical resistance than polyesters, and are often used in applications where corrosion is a concern, bridging the gap between polyesters and epoxies.

- Thermoplastic Resins: These polymers can be repeatedly softened by heating and hardened by cooling. While less common in the highest-performance "advanced" composites traditionally, their use is growing due to potential for faster processing and recyclability. Examples include PEEK and Nylon.

- Thermosetting Resins: These resins cure (harden) through a chemical reaction, often initiated by heat or a catalyst, and cannot be remelted.

- Additives and Modifiers: These are often mixed into the resin by custom chemical manufacturers to achieve specific properties.

- Fillers: Can reduce cost, improve dimensional stability, or modify density.

- Flame Retardants: Crucial for applications in aerospace, transportation, and construction where fire safety is paramount.

- UV Stabilizers: To protect the composite from degradation due to sunlight exposure.

- Colorants/Pigments: For aesthetic purposes.

- Toughening Agents: To improve impact resistance of brittle resin systems.

The specific combination of fiber and matrix, along with any additives, is carefully chosen to meet the performance requirements of the final product. This is where deep material science knowledge and often custom chemical formulation become essential.

What is the manufacturing process for composite materials?

We know the ingredients and some preparation methods. But what does the overall manufacturing journey look like from start to finish? Understanding the complete process helps us spot areas for improvement and manage production effectively. Let's look at the typical steps.

The manufacturing process for composite materials generally involves several key stages: preparing the mold, laying up the reinforcement and matrix, curing the composite, demolding the part, and then any necessary finishing or post-processing steps.

Composite manufacturing process flow

Let's dive deeper into the entire lifecycle of creating a composite part. It's more than just mixing fibers and resin; it's a carefully orchestrated sequence of steps.

Typical Manufacturing Stages:

- Tooling and Mold Preparation:

- Mold Design and Creation: The first step is to create a mold (or "tool") that defines the shape of the final part. Molds can be made from various materials like aluminum, steel, composites, or even wood for prototypes, depending on the production volume and curing process.

- Mold Release Application: The mold surface is meticulously cleaned and treated with a release agent. This is critical to ensure the cured composite part can be easily removed from the mold without damage. I've seen entire parts ruined because of poor mold release – a frustrating and costly mistake.

- Lay-up (Material Deposition):

- This is where the chosen preparation method (hand lay-up, RTM preform placement, filament winding, etc.) is executed. The reinforcing fibers and matrix resin are combined and placed into or onto the mold according to the design specifications. For prepreg materials (fibers pre-impregnated with resin), this involves carefully cutting and placing plies of material. The orientation of the fibers is critical for achieving the desired strength and stiffness in different directions.

- Curing (Solidification):

- This is arguably the most critical stage where the liquid resin solidifies and bonds with the fibers to form a rigid structure.

- Methods: Curing usually involves applying heat and sometimes pressure.

- Room Temperature Cure: Some resin systems can cure at ambient temperatures, often used for large structures or when ovens are impractical.

- Oven Cure: Parts are placed in an oven at a specific temperature profile for a set duration.

- Autoclave Cure: This is common for high-performance aerospace components. The part (still in its mold and often vacuum-bagged) is placed in an autoclave, which applies both high pressure and elevated temperature. This helps consolidate the laminate, reduce voids, and achieve maximum mechanical properties.

- The cure cycle (the specific ramp-up of temperature, hold times, and cool-down rates) is precisely controlled and is often developed in conjunction with the custom chemical manufacturer who supplies the resin system. Getting this wrong can lead to under-cured, warped, or weak parts. I recall a project with complex, thick laminates where we had to work for weeks with our resin supplier to fine-tune a step-cure cycle to prevent exotherm (runaway heat generation) and ensure a complete cure throughout the part.

- Demolding:

- Once the part is fully cured and often after cooling, it is carefully removed from the mold. This step requires care to avoid damaging the part or the mold.

- Finishing and Post-Processing:

- Trimming and Machining: Excess material (flash) is trimmed from the edges. Holes, slots, or other features may be drilled or machined. Machining composites can be challenging due to their abrasive nature and tendency to delaminate if not done correctly.

- Surface Finishing: Parts might be sanded, painted, or coated for aesthetic or protective reasons.

- Assembly: Composite parts may be bonded or mechanically fastened to other components.

- Inspection/Quality Control: Throughout the process, and especially at the end, parts are inspected for defects, dimensional accuracy, and sometimes undergo non-destructive testing (NDT) like ultrasonic inspection to check for internal flaws.

Each step requires precision and control to ensure the final composite part meets its design specifications and performance requirements.

Conclusion

Exploring advanced composites and custom chemical manufacturing shows how closely they are linked. Understanding this empowers innovation and smarter production across many industries.